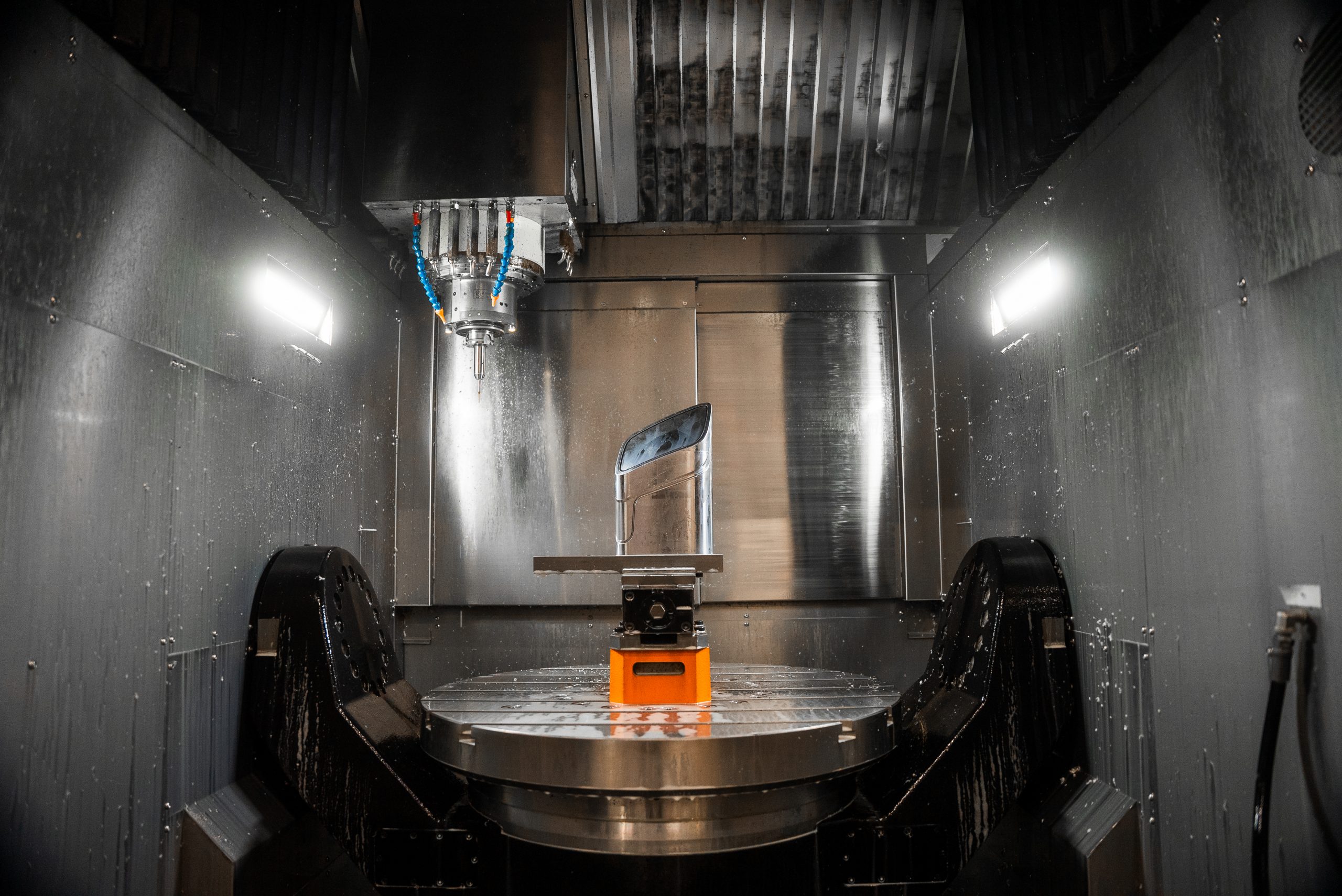

Toolmaking

Toolmaking is a specialised area of mechanical engineering that focuses on the development and manufacture of tools that are used in various manufacturing processes. These tools can range from simple hand tools to highly complex machines and devices.

From shaping stone hammers to forging robots, toolmaking transcends time, transforming ideas into instruments that empower progress. Through craftsmanship and ingenuity, it empowers us to build, solve, and create, shaping the world around us, one tool at a time.

Tool design

A central aspect of toolmaking is tool design. This involves the planning and design of tools to ensure that they function efficiently and deliver the desired results. The design may also include the selection of appropriate materials and manufacturing techniques. Tool design requires a deep understanding of the requirements of the manufacturing process and the ability to develop innovative solutions to fulfil these requirements.

Mould design is also closely linked to manufacturing engineering. This involves the selection and application of processes to produce tools, such as casting, forging, milling, turning and grinding. These techniques require a high degree of precision and expertise to ensure that the tools produced meet the specific requirements of the manufacturing process.

We support you

Overall, toolmaking contributes significantly to the efficiency and quality of manufacturing processes. By developing and manufacturing high-quality tools, toolmaking enables the production of products that meet customer requirements. In addition, toolmaking contributes to innovation in the manufacturing industry by developing new and improved tools that increase the efficiency and quality of production.

It is therefore an indispensable part of mechanical engineering and plays a crucial role in the modern manufacturing industry. By continuously improving tool technology, toolmaking helps to increase the competitiveness and performance of the manufacturing industry.

Every great achievement starts with a tool. Don't let limitations hold you back. We believe in your ideas, and we're here to help you turn them into reality.

Our mission:

Optimized production

We optimize your processes. Costs are reduced. We are driven by quality and individuality.

Create value

Creating complex solutions for our customers is the most important thing for us – simply our core competence.

Toolmaking FAQs

Metal Competencies offers a comprehensive service package in toolmaking that is characterised by high quality, innovative solutions, fast delivery times and customer proximity. The company has many years of experience and is certified according to DIN EN ISO 9001. Metal Competencies is therefore an ideal partner for companies looking for an innovative, reliable and high-quality toolmaking company.

Metal Competencies serves various sectors in toolmaking, such as automotive, aerospace, electronics and medical technology. The company has many years of experience and is known for its innovative solutions, high quality and fast delivery times.

Working with Metal Competencies in toolmaking takes place in just a few steps: Enquiry, consultation, quotation, order placement, development & production, acceptance & delivery, maintenance. The company is characterised by quality, flexibility and customer proximity.

Metal Competencies fulfils the highest quality standards in toolmaking. The company is certified according to DIN ISO 9001 and focusses on precision, quality, reliability and customer satisfaction. Metal Competencies is in close contact with associations and organisations that promote quality in toolmaking.

The most important requirements for toolmaking are precision, quality, reliability, flexibility, cost-effectiveness, efficiency, profitability, adherence to deadlines, quality assurance, customer service, conservation of resources, energy efficiency, recyclability, occupational safety and health protection.